Why Consumer Impressions of 3D Printed Products Miss the Mark

Share

The world of 3D printing and additive manufacturing is evolving rapidly, yet many consumer perceptions still fail to capture its true potential. At Revizion 3D, we see firsthand how outdated views limit appreciation of the transformative benefits of this technology. Let’s dive into why the promise of 3D printing—its unmatched customization, cost-effectiveness, and efficient manufacturing—is often underestimated.

The Customization Revolution

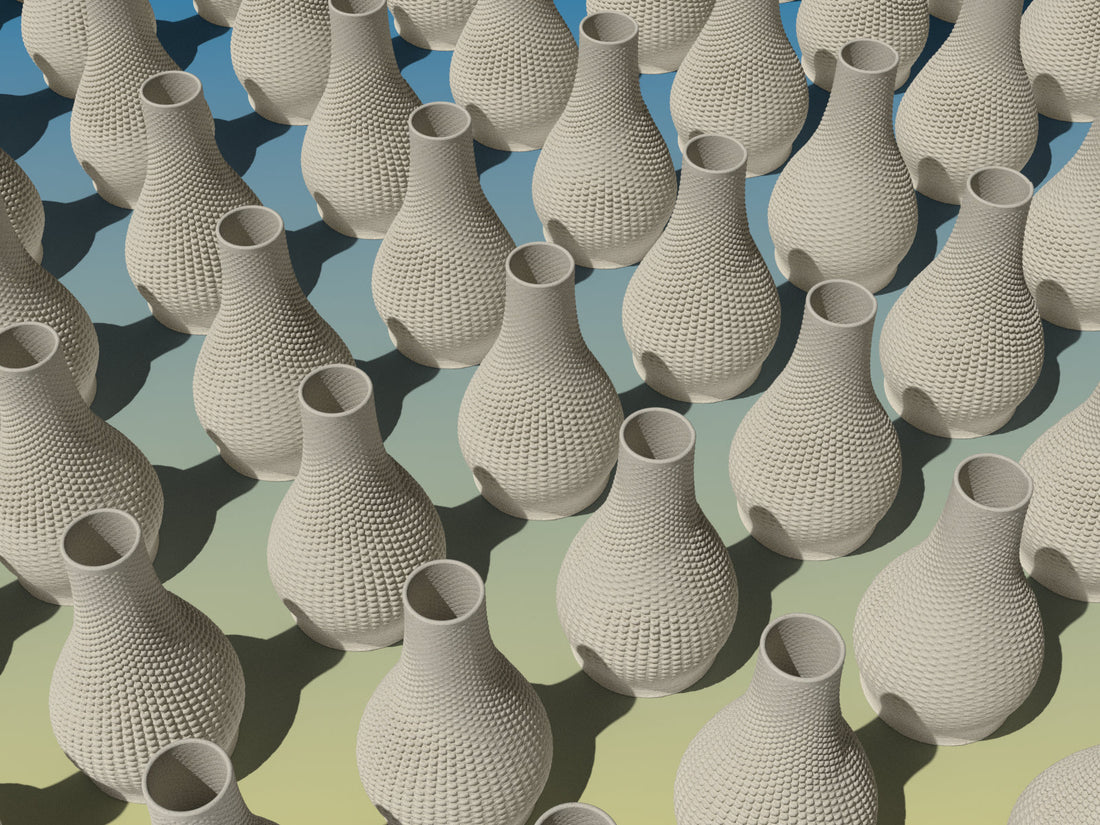

One of the most significant advantages of additive manufacturing is its ease of customization. Unlike traditional manufacturing that relies on expensive molds and rigid designs, 3D printing allows for infinite design variations. Consumers and businesses alike can now personalize products to suit individual tastes, needs, and innovations. However, many consumer impressions linger on the notion that 3D printed products are generic or prototypical. The reality is that without the constraints of mold making, every product can be uniquely tailored—be it for aesthetic appeal or functional optimization. Embracing this level of personalization not only enhances user experience but also sets the stage for unique design solutions in various industries.

Cost-Effective Manufacturing Without Molds

Another major benefit that remains underutilized is the cost effectiveness of eliminating mold making. Traditional manufacturing often demands hefty upfront investments in tooling and molds, leading to high minimum order quantities. This barrier has historically sidelined small businesses and startups. With 3D printing, the need for molds is eradicated, paving the way for lower production costs and reduced risk. This democratization of production empowers innovators to enter the market with minimal investment, fostering a landscape where low minimum order quantities and a lower barrier to entry become the norm. It’s time for consumers to recognize that these savings directly translate to competitive pricing and enhanced product variety.

Efficient and Sustainable Production

Additive manufacturing offers an efficient production process characterized by low waste and flat cost structures. Traditional manufacturing often results in significant material waste due to subtractive methods. In contrast, 3D printing builds objects layer by layer, using only the material that’s necessary. This efficiency not only reduces environmental impact but also contributes to flat cost of goods sold (COGS), making production predictable and scalable. Despite these advantages, many consumers still associate 3D printing with niche applications or experimental prototypes. Recognizing the robust, sustainable manufacturing process behind 3D printed products is crucial to appreciating its full value.

Bridging the Perception Gap

At Revizion 3D, our goal is to shift consumer perceptions by highlighting how these technological benefits translate into everyday advantages:

- Tailored Solutions: Unique designs and personalized products are now within reach.

- Lower Costs: With no expensive molds, production costs drop, offering more competitive pricing.

- Sustainable Practices: Efficient manufacturing with minimal waste is better for the planet and your wallet.

By understanding these key benefits, consumers can see past outdated stereotypes and appreciate the true potential of 3D printing. As the technology continues to advance, its integration into mainstream manufacturing is poised to redefine industries—making customized, cost-effective, and efficient products the new standard.

Embrace the future of production with Revizion 3D—where innovation meets practicality, and every product tells a unique story.